| | Erik Shauver’s Blitz Tech and Teardown Thread |  |

|

|

|

| Auteur | Message |

|---|

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Erik Shauver’s Blitz Tech and Teardown Thread Sujet: Erik Shauver’s Blitz Tech and Teardown Thread  Mer 17 Mar 2010 - 18:35 Mer 17 Mar 2010 - 18:35 | |

| hello voila un post que j'ai trouvé sur un autre forum qui vous sera surement utile je ferais la traduction petit a petit quand j'aurais le temps http://www.rcshortcourse.com/forum/showthread.php?t=2698 - Erik Shauver a écrit:

- Ce post est conçu pour être une référence rapide pour le Blitz. Il couvrira démontage, tuning, et infos tech. Je vais aussi essayer de vous donner quelques idées sur ce qu'il faut apporter à la piste et vous donner quelques "vieille école" aperçu de certaines techniques d'entretien que j'ai appris au fil des ans. Ce premier poste offrira des liens vers les postes concernés.

Je vais essayer ajouter de nouveaux thèmes pour aider à réglage, l'entretien, et en soulignant les caractéristiques.

First up:

Gearbox Maintenance

Rear Suspension Mount Swap

Front End Removal/ Servo Saver Setting

Steering Rack

Steering Servo Horn Alignment

Setting Toe

Camber/ Ride Height

Electronics Swap Post 1

Electronics Swap Post 2

PAGE 2 sur le forum

Electronics Swap Post 3

Electronics Swap Post 4

Setups 1

Bowties on Blitz Wheels

Inline Steering Blocks

Hub Spacing

Shock Oil

Shock Spring Rates

Shock Bleed/ Rebound

Steering Bushing/ Bearing Size

Setup, Hot Rod, 1/5/2010

PAGE 3 sur le forum

Spielwarenmesse Nürnberg, Feb 4th - 9th

Turnbuckle Length Chart

Setup Board and Corner Weights

centralized weight

different wiring

Dernière édition par Gilou le Mer 17 Mar 2010 - 19:14, édité 2 fois | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Train AR Sujet: Train AR  Mer 17 Mar 2010 - 18:35 Mer 17 Mar 2010 - 18:35 | |

| I wanted the gearbox to be as easy to access as possible. I’m not necessarily worried about screw count as I am with how easy it is to actually get to it and put it back in. A lot of the rear brace and rear bulkhead design was done with this in mind. Also, I took advantage of the pivoting of the bumpers to integrate maintenance with styling and chassis protection. Let’s dive in!  First take out these 8 screws.  Now these two screws. You’ll likely need an x-acto knife or a dental pick to get the dirt out of the screw sockets.  Rotate the bumper and brace assembly back.  That’s it! You’ve got your gearbox out and ready for maintenance. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Train AR Sujet: Train AR  Mer 17 Mar 2010 - 18:36 Mer 17 Mar 2010 - 18:36 | |

| Rear Suspension Mount Swaps To change the rear toe is very similar to the gearbox access. However, you take out less screws and use the flexibility of the bumpers to your advantage.  Remove these screws.  Flip the chassis over and remove these screws as well.  Bend the Rear Skid Plate up. Push the arm brace (susp mount) off the gearbox locating pegs. Then pull it back away from the truck. That’s it!  To reinstall, put the mount on both pin, then push the mount onto the grearbox pegs. Then put your 2 lower screws back in to hold thing in place while you put the rest back in. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Train AR Sujet: Train AR  Mer 17 Mar 2010 - 18:36 Mer 17 Mar 2010 - 18:36 | |

| It's been covered already, but one of the fastest ways to pick up steering is to set the servo saver tighter. Short of adjusting the nut in place, this is the easiest way to remove the front end.  1. Remove these 2 screws.  2. remove 2 screws  3. remove 2 screws  4. remove 3 screws  5. front end in hand!!  6. remove this screw for servo saver spring access  7. rough setting for max steering while retaining some protection... too tight like gluing and locking down the saver (YES we tried it) will make the front end unpredictable on 1 wheel landings.

Dernière édition par Gilou le Mer 17 Mar 2010 - 18:38, édité 1 fois | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Reglages direction Sujet: Reglages direction  Mer 17 Mar 2010 - 18:37 Mer 17 Mar 2010 - 18:37 | |

| The steering rack position will make a huge difference in driving feel.  1. the standard rack hole is the rear hole, it promotes an easy to drive, forgiving setup  2. the forward hole will offer a more aggressive initial turn in and hold mid corner grip better for your Blitz You will need to modify your toe settings to compensate.

Dernière édition par Gilou le Mer 17 Mar 2010 - 18:38, édité 1 fois | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Reglages direction Sujet: Reglages direction  Mer 17 Mar 2010 - 18:38 Mer 17 Mar 2010 - 18:38 | |

| First things first, are the steering linkages (ball cups + turnbuckles) the same length? Next up, the servo horn (arm) should not be 90* from the chassis plane for most servos. It should be about 8* from vertical. You have two arms pivoting and essentially scribing arcs, so things are a little more involved. Also, when you swap out the servo, the axis of the servo arm can change compared to stock. Image Info: The green radii shown are for the wheels pointing straight ahead. The blue are for turning right. The red are for turning left. The 8* estimate is dependent on your servos output position and also the drag link length, which you can make longer.  Also, at some point, the stock radio and it's lack of EPA (end point adjusment) is going to be the limiting factor. However, setting your horn about 8* from center will help a lot. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Reglages Trans AV Sujet: Reglages Trans AV  Mer 17 Mar 2010 - 18:39 Mer 17 Mar 2010 - 18:39 | |

| Which leads us to setting and measuring the front toe. While not the most precise way to do this, a ruler is simple and repeatable. Use the metric side. With the truck otherwise setup ready to drive, install a set of wheels with no tires. We're looking for the difference between the front and the rear.  use a long ruler with your "setup" wheels to check the front  now check the rear  In this case the difference was about 3mm which is about 1 degree of toe out (roughly 2.8mm = 1 degree). As the chassis is so sensitive to ride height and camber settings while turning, you'll need digital calipers to really nail this down. However, so long as you are consistent, a ruler works just fine. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Reglages Trans AV Sujet: Reglages Trans AV  Mer 17 Mar 2010 - 18:40 Mer 17 Mar 2010 - 18:40 | |

| If we're going to talk setups, one thing we need is to be on the same page as far as setup procedure. Some of you may have better methods (please show them off), however these I'm going to show are repeatable. These items are necessary for consistency and to begin fine tuning your truck for serious track duty. If you’re skipping any of these items and wondering why your truck is inconsistent… wonder no longer. There are several other things that can be done and measured, but I feel these are the basic essentials considering how much of a beating these things take.   1. Lets start with camber. Get yourself an extra set of wheels and use them for setup duty. Use a gage and note that the Blitz has an extreme amount of camber gain potential in their design. So when you change camber, it affects ride height and vice versa. Press down on the truck a few times to find the settling point. Then measure and adjust. You may have to do this and set ride a few times to get it even. 2. Set your front toe while the “setting” wheels are still on your truck. Take a mm measurement at the front and at the back of the front wheels. The difference between these two is what you are looking for. A measured difference of about 2.8mm equals 1 degree of toe. See Setting Toe Post   3. Install all your running gear and get the truck ready to drive. Grab some gages of your choice and measure ride height. We do everything metric, so this truck is set with the rear at 34mm and the front at 35mm. You can use this to change the basic balance of your truck and tailor the height to how rough your track is. In the pictures I'm using a 20mm Hudy gage, a 10mm Hudy gage, and then a ramped Hudy ride height gage that has gradations for half mm.  4. The stock camber washers are 1mm. You will easily notice 0.2mm of change on your handling and lap times. Use combinations of Z813, Z814, and Z815's to get the desired ball stud heights at the inner camber link pickup points. 0.5mm, 0.75mm, and 1mm... i.e. 0.5 and 0.75 to get 1.25mm, etc. www.hpiracing.com/products/en/Z813/ www.hpiracing.com/products/en/Z814/ www.hpiracing.com/products/en/Z815/   5. Use marker, pens, and notes to help wherever you can. I like to label tires so I know where they have been used and whether they are being rotated or not. It also helps chasing down inconsistent handling issues. Tick marks on the shock collars will aid in getting things set evenly and allow more even changes. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Instalation radio Sujet: Instalation radio  Mer 17 Mar 2010 - 18:40 Mer 17 Mar 2010 - 18:40 | |

| This is often referred to as I “just changed my electronics.” For experienced enthusiasts and racers, that’s all that is needed as this is one of our favorite parts of R/C. For the fresh RTR buyer, this is the most daunting part of owning an R/C vehicle and the quality of the installation DIRECTLY affects performance. Component selection and merits can be discussed elsewhere as the focus here is to get your chosen gear into the truck in the most effective manner. I welcome comments from veterans as I don’t expect everyone to have the same procedures or techniques. That’s the hobby part that all the “old school” guys love about R/C. Everything I’ve done is a mixture of my experiences mixed with observations of going to the track with professional racers and seeing their setups and installations. I also build a lot of mountain bikes, so I mix in a healthy dose of that experience as well.  1. Start by gathering up your gear you want to install. Have a charged pack ready. Pick up some quality 3M double stick tape. I only use Scotch #4353 Indoor/ Outdoor Mounting Tape (Super Heavy Duty). It is a grey tape, about 1.2mm thick with red backing. It has best hold of any tape I’ve tried that removes cleanly. It is easily found at Lowes/ Home Depot type places and comes in rolls of about 12 yards. Store it in a plastic bag and it lasts a long time!  2. Pull the outmost 2 screws to remove the servo sub-assembly.  3. Pry off the rest of the standard electronics.  4. Clean off the residue with your motor spray of choice.  5. Trim off the ESC bosses flush to the face as they currently have no use.  6. mmmm, way too much servo = just right!  7. the stock servo horn has 25 splines  8. center your servo with the receiver and ESC to be installed, then install the horn appropriate for your servo (23 splines = JR/ Sanwa/ KO, 24 = Hitec, 25 splines = futaba)  9. remove the 4 screws and washers only  10. flip your chassis over and use the boss locating holes as a guide to loosely install your servo. press down on the servo while centering it and secure the fasteners (this gives the lowest possible CofG) | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Instalation radio Sujet: Instalation radio  Mer 17 Mar 2010 - 18:41 Mer 17 Mar 2010 - 18:41 | |

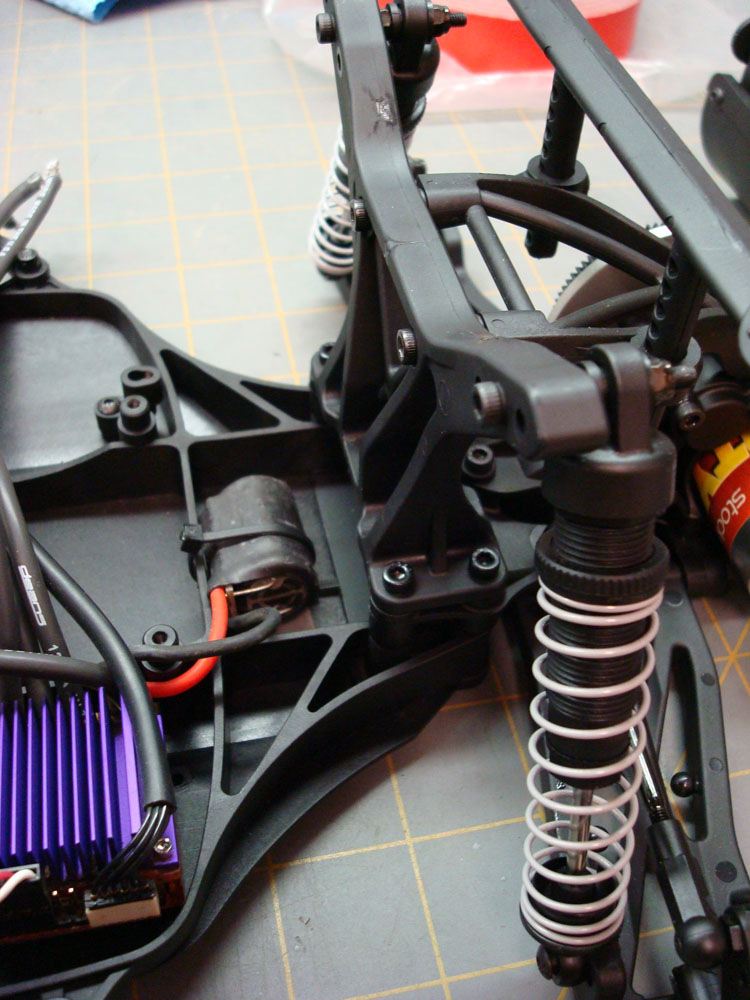

|  11. reinstall sub with new servo and reattach ball cup  12. I like to ensure that my leads don't have a stresses on them, so I create anchor points by drilling the chassis  13. loosely attach the lead with zip ties  14. Since this swap is to a 17.5 system, I'm installing a 77 tooth spur. I like to simplify the final assembly by tacking the slipper pads to the spur with a drop or two of CA. Note that the dark side of the pads is to contact the metal slipper plate while the lighter colored side is to contact the gear. For a 10.5~13.5 application use the 83 Spur. For the stock Fireball 15, 8.5,or hotter winds, use the standard 88 Spur.  15. clean your rings (mainly to remove any glazing or oils)… I also put tick marks on rotating parts so they get reinstalled how they came off.  16. Note that the processing of the plates gives a rounded edge to one side. I orient this rounded edge towards the die cast slipper carrier parts to ensure they fully seat (read to reduce wobble).  17. This is a great time to break out a sharpie and add tick marks to count turns. A good starting point for the slipper is to tighten until the spring is fully compressed, then loosen the nut 1.25 to 1.5 turns. (This is contrary to the typo in the manual that states 6 turns)  18. I further measure my settings with calipers whenever I am doing any maintenance so I can get it setup similar to previous settings. Note that this assembly “floats.” You can push on one side of the spur and induce a wobble. You can also push to REMOVE wobble. In action, it is a very sound setup. For bench racing, I’m sure it’ll give veterans fits! LOL  19. loosely mount your ESC to check your lead lengths and intended position for clearance, reach, etc  20. Grab a silver Sharpie and mark the front outside corner. This will make it easier to place with servo tape (double sided, 3M preferably) later. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Instalation radio Sujet: Instalation radio  Mer 17 Mar 2010 - 18:41 Mer 17 Mar 2010 - 18:41 | |

|  21. If your ESC has a separate capacitor (as this GTB does), I like to mount it securely in the chassis. Start by drilling hole(s).  22. Use some small zip ties to tether the cap to the chassis.  23. Use a small piece of servo tape to absorb shock and hold the cap in place.  24. Loosely strap it down with ties. Remember they are a tether of sorts to keep it in place should the servo tape fail. If overtightened, you'll crush your cap!  25. Part of why I don't mount the ESC in the rear cavity under the tower is as follows. Pull the top 4 tower screws.  26. Remove the 4 lower screws.  27. Now twist the whole rear end forward.  28. Now you have the rear end in your hand!! This is great for several reasons. First, if you build up a stock rear end and a mod rear end, you can run two classes with a quick 5 minute pit routine. Further, it gives much easier access for cleaning out debris and mud should you race in damp conditions.  29. While we've got the rear end off and out of the way, let's cutomize the battery retainer height to match our race packs. The brace will accomodate 23mm if you flip the brace over. The standard height will accomodate 25mm thick packs. I added a 2, 1mm spacers to accomodate my 26mm packs.  30. test fit for clearance | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread  Mer 17 Mar 2010 - 18:42 Mer 17 Mar 2010 - 18:42 | |

|  31. as my batteries won't allow a full three foams, i've cut down a block for perfect fit. This also allows me to fine tune front to back position.  32. test fit of the cut block  33. to reinstall the rear end, slide on the lower part first  34. now bend up the front and pull over the locating bosses  35. Tighten 8 fasteners and you're set! Don't forget to solder or connect your electronics.  36. check for wire clearance at the linkage  37. Finally, route your ESC leads. Since this lead is twisted, I un-twisted it so they would lay flat in the lead groove.  38. I add decals or electrical tape to protect and hold down the lead. Also, this is a good spot to add a lot of tape and cover up the chassis holes. This prevents dirt from entering from the bottom of the chassis.  39. I also drill here to secure the on/off lead in case of tape failure.  40. loosely strap this lead to control the direction of pull should your tape fail in bashing conditions (or racing if it’s very rough)  41. More drilling - anchor point for Rx wiring  42. Mounted Rx and cut to fit antenna tube  43. strapped in wiring... prevents wires from moving excessively and taking damage from heavy crashes...  44. Calibrate your ESC, check your steering EPA, and you're ready to move on to track prep and chassis setup! | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Setup Sujet: Setup  Mer 17 Mar 2010 - 18:46 Mer 17 Mar 2010 - 18:46 | |

| Here are some of the setups we've been running.

The stock setup was something that seems to get the truck around just about any track with confidence. It may not have the most initial steering, but throttle and brakes are your friend with that setup. It also likes a lot of motor.

After we've gotten some more track time, we've headed in these setup directions:

OC/RC starting

Outdoor, Loose Track

Setup Testing

Blank, Editable

The OC/RC setup is an adaption of one my setups mixed with what I liked from Thad Garner's setup. I stress these are just starting guidelines to try. The outdoor setup is similar to the stock setup, but with much more precise settings/ feel. The "setup testing" setup is what I plan to throw down next time we go to West Coast or OC/RC. It is a mixture of what I know I like and to find the rotation everyone seems to want without loosing the rear forward bite. Lastly, an editable setup sheet.

The shock length listed is from center to center. If you're measuring max hole to hole (direct measurement), add 5.6mm to my measurements. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread  Mer 17 Mar 2010 - 18:47 Mer 17 Mar 2010 - 18:47 | |

| I noticed some fitment issues with certain inserts (the newest molded inserts from PL, light grey in color) with Bow Ties and HPI wheels. Their carcass design has a lot of features tailored to their beadlock system that don't play nice with our wheels. Also, the inserts seem to be straight off 1/8th buggies. To get them to fit our wheels, you need an x-acto knife or a razor blade to trim the inserts. It's actually much easier than it sounds.  this is the stock Proline insert mounted with a lot of patience (read that as swearing), rubber bands, and tire manipulation. You can see how flat the tire stretched out side to side. Also note the 3.0 diameter side of the insert is already compressed.  To correct this and make installation a lot smoother, you can trim out this area with an x-acto. Trim right along the mold parting line on the side and then again on the inner diameter.  This allows the bow ties to install on our wheel without pre-compressing the insert and also holds a more natural carcass shape without the prior stretching. They glue up much nicer after modded. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread  Mer 17 Mar 2010 - 18:49 Mer 17 Mar 2010 - 18:49 | |

|  1. Trailing installed, inline awaiting swap  2. remove two screws, two washers, one flanged bushing  3. remove axle, spacer, and hex  4. swap the ball stud, keeping only the 1mm washer... ball stud is installed on the side with the rib  5. ball stud installed, swap bearings and reinstall axle without the aluminum spacer  6. inline installed, trailing with extra washer and axle spacer | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread  Mer 17 Mar 2010 - 18:51 Mer 17 Mar 2010 - 18:51 | |

| This technique applies for the front or the rear arms. For the front you will be modifying steering geometry and wheelbase. For the rear, hub spacing will modify the wheelbase and the drivetrain angle.  1. To adjust the steering geometry, move the C-hub spacer.  2. remove screw, use 1.5mm driver to slide out pin while holding parts in place... this will save a lot of aggravation looking for lost washers!  3. The parts aren't going anywhere while the drive is acting as the hinge pin. Now is a good time to check your pin.  4. push pin back in half way and drop out the spacer  5. reinstall spacer and push pin back in while using driver for alignment  6. replace screw | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread  Mer 17 Mar 2010 - 18:53 Mer 17 Mar 2010 - 18:53 | |

| Hey guys, I wanted to share some info so we care more easily share shock data. To start, let's cover oil "conversions." The most appropriate unit to list the kinematic viscosity is in centistokes (cs). However, since the past rivalry of TA and TL was so intense, I'm guessing they wanted to hide the true measure of the oils and assigned an arbitrary "weight" to them. This makes it a bit difficult to compare shock setups without knowing the oil brand.

Quite a few companies list their oils in a straightforward manner: Xray, Mugen, Kyosho, HB,

For these oils, the number on the label is almost exactly the centistoke value of their oil (within in a tolerance range, +/- 20ish?). So 300 Mugen is very close to 300 Kyosho.

HPI oil (bear with me as I did not pick this ), is listed as "weight," but in acuality, a modified version of a centistoke labeling. Just add a zero to our label weights to get the true centistoke value. 35 "weight" = 350, 40=400 and so on. So our oils will compare directly to those in the list above.

Now for the TA/ TL oils... I've got a list of the cs values for each weight (measured) for comparison.

TA

10=108

20=208

25=286

30=373

35=454

40=525

50=707

60=725

70=960

80=1040

TL

15 =110

17.5=158

20 =243

22.5=243

25 =294

27.5=345

30 =381

32.5=397

35 =459

37.5=477

40 =546

45 =657

50 =886

60 =844

70 =970

So, if I wanted to use an Asian/ Euro oil to match say a Losi 70, I need either a 900 or 1000 (yes diff oil).

Hopefully this helps when sharing shock data! | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Shock Spring Rates Sujet: Shock Spring Rates  Mer 17 Mar 2010 - 18:54 Mer 17 Mar 2010 - 18:54 | |

| @PROBIE and cyoder#9: I finally got to try #3 at the track. If I recall it resulted in toe in after the flip. It had an "out of range" feeling and had interference with the shock. It turns in unpredictably and had snap oversteer. I tried it in combination with my "setup testing" settings. Otherwise that setup had a lot more steering and loosened the rear end up onsiderably.

@jkirkwood: I don't believe any of our other springs fit, but I'll need to check it out (perhaps Pro4? will have to check my drawings). The best bet for your power issue would be to add a capacitor to your setup. This post by Recce01 should do the trick.

@bda52: While the setup sheet lists that setting as kick-up, it's actually anti-squat. It helps control weight transfer to the rear under acceleration. +2 keeps more weight on the front wheels. +1 allows more transfer.

@Matt Sunderlage: Re: bump steer washers. With the drastic change of going to inline blocks and moving to the front steering hole, a slight amount of bump steer can be induced. I tend to try to tune it out, or keep it slightly "bump out." Camber link changes can affect bump and camber gain, so it's something to continually keep an eye on. Generally you're looking for a washer stack between 1-3.5mm.

Spring Rates:

Front: Red 5lb, Yellow 4.5lb, White 4lb, Pink 3.5lb

Rear: Red 4lb, Yellow 3.5lb, White 3.2lb, Pink 2.9lb | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Shock Bleed/ Rebound Sujet: Shock Bleed/ Rebound  Mer 17 Mar 2010 - 18:56 Mer 17 Mar 2010 - 18:56 | |

| After your basic fill (awesome XRC link above btw), note the orientation of the notch in the shock body. Add a tick mark to aid in finding it.  This notch is what allows the air to come out of the shock.  1. I put the cap on about 80% of the way on, then (2.) tilt the shock with the notch facing towards the top.  Now, (3.) push the shaft into the body to bleed out the air and excess oil. Then, (4.) close the cap. For the rear, (5.) pull the shaft back out and (6.) open the cap to the previous position. (7.) push the shaft in a second time to remove more oil. (8.) close the cap again. The rear shock has more volume, but with less volume compensation, so the second pass takes care of this. At this point you should cycle the shock shaft to check for air. If done right they will be smooth and air free. If you hear air and feel some inconsistency, time to refill and re-bleed. Also, you can check the rebound amount and speed between pairs of shocks. I like to match mine in pairs. One major advantage of the option shock tops is how they bleed more like an 1/8th scale shock.   You screw the cap on about 80% again, getting rid of some of the oil. Then tilt the shock again, this time keeping one hole "up" and one hole "down."  This tilt allows air to escape through the top and excess oil out the bottom hole. I do one shaft plunge for the front and two again for the rear. This is a rough guideline though as rebound speed and amount should be the final check.  about 14mm from cap bottom to bump stop top I consider 0-5mm a fairly dead shock. 5-10mm is "more rebound" or quite active. Anything significantly over 15mm or so is risking loss of oil and sucking the bladder back into the body. It is definitely an area to explore for tuning.  Finish up with the shock wrenches to lock down the caps. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Steering Bushing/ Bearing Size Sujet: Steering Bushing/ Bearing Size  Mer 17 Mar 2010 - 18:57 Mer 17 Mar 2010 - 18:57 | |

|  While you've got the front end off, you might as well go ahead and replace the bushing with bearings! You know you want to! (B013's or your favorite brand 3x6x2.5mm) | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Setup, Hot Rod, 1/5/2010 Sujet: Setup, Hot Rod, 1/5/2010  Mer 17 Mar 2010 - 19:02 Mer 17 Mar 2010 - 19:02 | |

| We were testing a few parts out at hot rod last night and I got a few setup sheet post requests. My truck was great in practice and during the first qualifier heat. However, the rear grip went away when it starting getting colder. So here's my Hot Rod setup: http://www.hpiracing.com/pdf/setups/Blitz_Setup_Beta_1.5.2010_Hot_Rod_web.pdf I'd likely change the oil to 550F/ 500R next time. Other than that, the truck jumped great, had plenty of steering, and loads of forward bite. I'm not sure if the cold messed up the truck or if it was my hands!! :mrgreen: Now if we could just run more motor than the 10.5 rule  | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Spielwarenmesse Nürnberg, Feb 4th - 9th Sujet: Spielwarenmesse Nürnberg, Feb 4th - 9th  Mer 17 Mar 2010 - 19:04 Mer 17 Mar 2010 - 19:04 | |

| Stay tuned to a cool upcoming article in Xtreme. We just tested a lot of differential settings at OC/RC!

Also, for those of you nearby or with access to internet coverage, you'll want to check out the upcoming Nürnberg toy fair!

http://www.toyfair.de/index.php?id=4&L=1

Also, try to keep this thread tech related and on topic, this isn't the place for chit chat or basic R/C questions. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Turnbuckle Length Chart Sujet: Turnbuckle Length Chart  Mer 17 Mar 2010 - 19:07 Mer 17 Mar 2010 - 19:07 | |

| 7-8mm is max for the front unless you take out the internal spacer. Then you could get 9-10mm. Sounds like you prefer a "dead" shock or a shock without as much rebound. This is great to know when you go to rebuild them again as you can start with them like that.  The Short turnbuckles are 60mm and the Long are 69mm. http://www.hpiracing.com/products/en/86878.html http://www.hpiracing.com/products/en/103369.html 400cst is the standard oil "weight." (HPI 40 weight). clic me!The stock pistons are A front and B rear. There are additional A,B, and C pistons included so you can adjust to your driving style and local tracks.  The hub carriers are 0*, so swapping them will only affect fore to aft position of the steering block pivot axis. Like everyone else, I was doing the Christmas and New Years family stuff! Hopefully everyone had a great Xmas with a Blitz under their tree :mrgreen: and great New Years! I did get to make it down to San Diego/ Pauma last weekend for some great "backyard racing!!" That was AWESOME!!!! Nice track Recce01!!! I don't think it was possible for that dirt to offer anymore grip!! That was even better than clay! And nice to meet you Cheatin!!

Dernière édition par Gilou le Mer 17 Mar 2010 - 19:13, édité 1 fois | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: Setup Board and Corner Weights Sujet: Setup Board and Corner Weights  Mer 17 Mar 2010 - 19:09 Mer 17 Mar 2010 - 19:09 | |

|  A Hudy 1/8th setup board with some mods (note three holes)  I drilled out three holes and added expanding brass inserts  The top side gets cone point set screws  Add in a bubble level and now you have a portable flat surface that can be leveled.  add four identical gram scales and now you can check your corner weights and weight balance  I did a quick check to see what the weights were with the battery forward and also with the battery all the way to the back. The truck was fully ready to drive. (grams) Pack forward: RF=433, LF=441, RR=704, LR=711 Pack back: RF=420, LF=429, RR=715, LR=722 So about 38% front weight compared to 37% with a 290g pack. It's surprising what 1% will do to your steering feeling :-o You can achieve even more with chassis rake. | |

|

| |

Gilou

Admin Tom Sawyer!

Messages : 668

Date d'inscription : 10/01/2010

Age : 37

Localisation : Laval Canada et tarbais et fier de l'etre

|  Sujet: centralized weight Sujet: centralized weight  Mer 17 Mar 2010 - 19:11 Mer 17 Mar 2010 - 19:11 | |

|  similar drilling of chassis as in this tech post-I'm shooting for more centralized weight... I would go further, but convenience aimed towards maintenance can become an issue without hand fabricating a battery strap/ component shelf. The Tekin fits in the rear "compartment" nicely. | |

|

| |

Contenu sponsorisé

|  Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread Sujet: Re: Erik Shauver’s Blitz Tech and Teardown Thread  | |

| |

|

| |

| | Erik Shauver’s Blitz Tech and Teardown Thread |  |

|